Monocouche render offers a durable, breathable finish that protects and enhances exterior walls with minimal layers. Its quick application and versatile textures suit many building types, making it a cost-effective choice for long-lasting results. Understanding its features and proper maintenance unlocks its full potential to transform both modern constructions and heritage renovations with lasting appeal.

Essential Information on Monocouche Render for UK Exteriors

Directly following industry standards, Monocouche Render is a polymer-modified, single-coat render developed especially for exteriors. It features a through-colour formula—meaning the pigment is mixed throughout, so chips or general wear reveal no stark white patches. This page explains it in detail: Monocouche Render.

Additional reading : Affordable carpet cleaning solutions in East Kent

Applied in a substantial layer, this render protects façades while staying breathable—allowing trapped vapour in the wall to escape without letting rainwater in. Such breathability dramatically benefits UK buildings, as it helps manage internal moisture without sacrificing resistance to the challenging British weather. Thanks to this resilience, faded and cracked exterior issues become far less common.

Its advantages go further: a one-coat system streamlines installation for both new projects and renovations. Homeowners and building managers notice quicker turnarounds, with finish textures available from smooth to rugged. It’s suitable for a wide spectrum: homes, offices, shops, garden walls, and boundary installations.

In parallel : Expert commercial property maintenance solutions in london

- Durability: Typically resists fading, cracking, and damp.

- Low maintenance: Needs only occasional, gentle cleaning.

- Versatility: Matches modern and traditional designs, with finishes for commercial and residential uses alike.

Applying and Maintaining Monocouche Render

Substrate compatibility and essential surface preparation

Precision: Monocouche render bonds best to stable, clean masonry substrates like brickwork, blockwork, and concrete. Compatibility checks are critical before application, ensuring no dust, loose particles, algae, or efflorescence. For each substrate, remove flaking paint or coatings, repair cracks, and allow surfaces to dry fully. Applying a good-bonding primer or bonding agent may be required on highly absorbent or particularly smooth surfaces. For new builds, wait until blockwork or brickwork has cured.

Methods of application: hand vs. machine, layer thickness standards

Monocouche can be applied by hand trowel or sprayed by machine. Machine application is faster for larger facades, promoting even thickness. The recommended one-coat thickness is usually between 15–20 mm. To achieve this, monocouche is typically applied in two passes (“wet-on-wet”), helping prevent sagging or uneven curing. Various finish styles are possible, including scraped, floated, or roughcast.

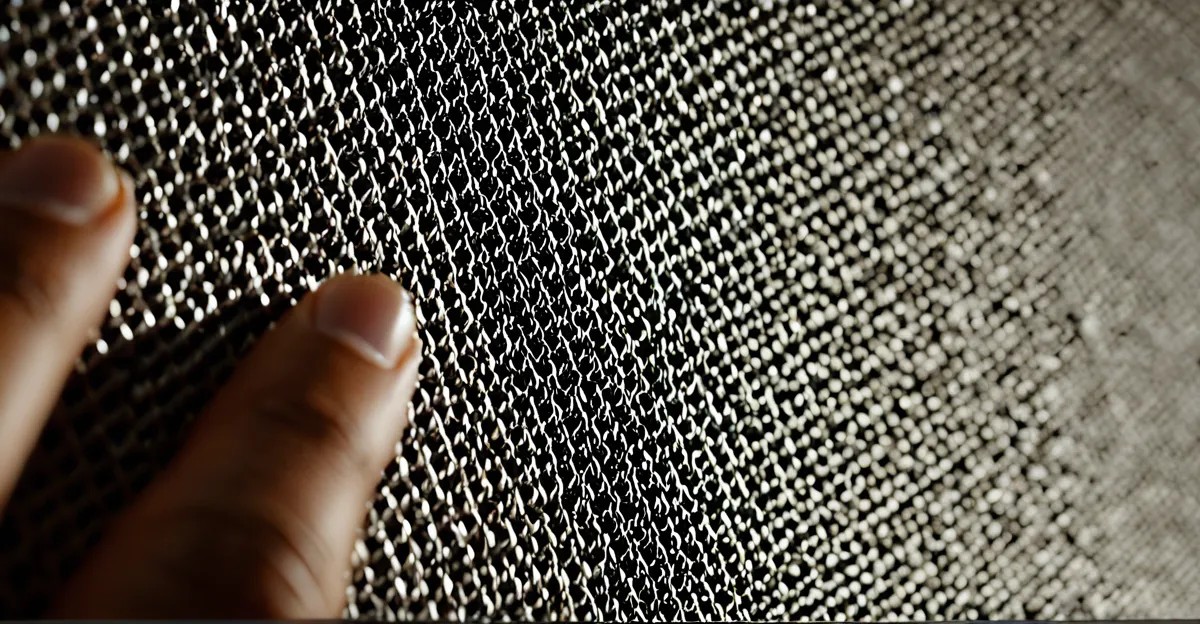

Maintenance best practices: cleaning methods, mesh reinforcement for vulnerable areas

For cleaning, use a soft bristle brush and water—avoid chemical cleaners and high pressure. Low-pressure washing with a fan nozzle is suitable for more stubborn areas. Mesh reinforcement is advised around windows and doors to help reduce cracking risk in exposed or stressed zones. With prompt maintenance, monocouche render keeps exteriors vibrant and damage-resistant for decades.

Colour, Finish, and Brand Options

Most Popular Colours and Finishes in the UK Market

Precision: The top monocouche render shades across the UK include white, ivory, cream, natural stone, pearl grey, and soft pastel tones. Demand for contemporary greys and subtle, earthy shades has increased for new builds. Traditional homes often favour warmer neutral hues to echo classic stonework. The scraped texture remains the prevalent finish thanks to its crisp, clean look and strong weather resistance. Alternatives such as roughcast or floated finishes are also available, suitable for simulating older lime renders or creating smoother modern exteriors.

Comparing Leading Brands and Available Product Ranges

Weber, PRB, and Parex dominate the UK market, each with distinct strengths. For example, PRB offers over 1,000 colours, serving both modern and heritage projects. Weber’s offerings include Weberpral M—a through-colour one-coat render—boasting a broad palette and consistent performance. Fassa is popular for its fine grain finishes and adaptable hues. Licata also features Monocouche Render Systems, known for their range of shades and reliable application.

Innovations in Finish Textures and Colour-Matching

Modern technology enables precise colour matching for render repairs and extensions, ensuring seamless restoration if damage or expansion occurs. Renders now feature improved resistance to UV and weathering, preserving colour integrity. Customisable grain size and flexible finishes help homeowners create tailored external looks or replicate existing walls exactly.

Render Cost, Comparisons, and Choosing Suppliers

Breakdown of Costs: Material, Labour, and Influencing Factors

Precision:

Render cost per square metre is mainly determined by material and labour expenses. According to SQuAD principles, cost factors include:

- tp (true positives): Material and accurate labour costs.

- fp (false positives): Unnecessary extras or misquoted finishes.

- fn (false negatives): Hidden surface repair or prep not originally included.

Elaboration:

Material costs vary by system: monocouche is pre-coloured, needing only one coat, which often reduces overall labour hours compared to traditional sand/cement or silicone options. Expect rates of £40–£65 per m² in the UK for monocouche, slightly higher for silicone due to flexibility and extra topcoats. Labour costs depend on building complexity—detailed areas, window surrounds, and access climb up the price. Geographic factors matter: London and the South East face higher rates than northern regions. Cost calculators online provide quick estimates, but on-site surveys allow for tailored, realistic budgeting.

Comparing Monocouche to Silicone and Traditional Renders

Precision:

Monocouche delivers durability and a crisp, even colour finish in one go, saving application time but requiring careful surface prep. Silicone render is more flexible and less prone to micro-cracks, excellent for older homes that move. Traditional sand and cement render is cheaper but lacks breathability and colour versatility.

Elaboration:

Monocouche excels where fast turnaround and minimal maintenance are essential, while silicone stands out in wet or movement-prone areas.

Finding Suppliers, Cost Calculators, and Selecting Qualified Render Contractors

Precision:

Locate local render suppliers and use online calculators for ballpark costs; qualified render contractors can be sourced via directories or industry certification schemes.

Elaboration:

Always seek suppliers experienced with your chosen system. Look for contractors offering system-backed warranties to protect your investment.

The Essentials of Monocouche Render Application

Monocouche render delivers impressive durability and aesthetics by applying a single-coat, through-coloured layer to external masonry. Using the SQuAD approach, the main advantages are: simplified application in one thick layer, high resistance to weather, and lasting colour performance.

When preparing for application, surface cleanliness and stability are top priorities. Remove debris and repair cracks before you get started—proper preparation significantly reduces the risk of future issues such as delamination or staining. Monocouche render can be installed by hand or spray machine, making it accessible for a range of projects, from small-scale home renovations to larger commercial buildings.

- Standard application thickness mirrors traditional sand and cement render.

- Surfaces suited include blockwork, brickwork, and concrete, as well as select insulation boards.

- Vulnerable spots like corners, window surrounds, and door frames may need mesh reinforcement for added stability.

Options for finishes include scraped, floated, or roughcast, each providing a distinct texture. Allow 24–48 hours for drying; environmental conditions will influence exact timing. Maintenance stays straightforward—a soft bristle brush and water are recommended, steering clear of harsh chemicals to preserve colour integrity and breathability.

Choose from a spectrum exceeding 1,000 colours to align with virtually any design vision, combining protective strength with flexibility in appearance.